Phone: +91-80-2843 7870 | Email: info@trinitycoating.com

Phone: +91-80-2843 7870 | Email: info@trinitycoating.com

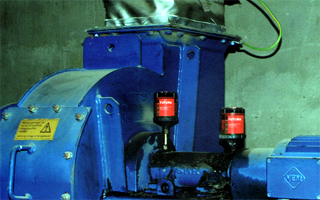

Productivity, equipment reliability and workplace safety are directly linked to key performance indicators of blowers and fans. This makes efficient maintenance of machines and equipment extremely important to plant operators. Numerous grease points on blowers and fans must be lubricated regularly at short intervals. Due to difficulties associated with access or safety during operation, it is common for some equipment to receive inadequate lubrication. This results in lubrication starvation, contamination entry and accelerated wear. Extreme operating conditions and limited labour resources call for reliable and tough lubrication equipment in order to prevent costly machine downtime.

Automatic lubrication systems from perma are successfully being used on blowers and fans worldwide. They are economical, meet technical demands and improve workplace safety.

Profitability and efficiency of pumps are directly related to equipment reliability. Correct lubrication is one of the main requirements for reliable operation and higher efficiency. Many pumps are not lubricateed as often as required because they are located in hard to access or dangerous areas. But insufficient and incorrect lubrication of bearings and seals results in accelerated bearing wear and the developement of impeller gland leaks.

All over the world perma automatic lubrication systems are being used to extend the service life of pumps. They are economical, meet technical demands and tremendously improve workplace safety.

► Housing: perma CLASSIC - metal / perma FUTURA - transparent plastics

► Electrochemical / grease and oil

► Operating temperature 0°C to +40°C

► Discharge period at 20°C with SF01: 1, 3, 6 or 12 months

► Pressure build-up: Max. 4 bar

► Lubricant volume: 120 cm³

► Housing: Transparent plastics

► Electrochemical / grease and oil / temperature independent

► Operating temperature -20°C to +60°C

► Discharge period: 1, 2, 3... 12 months

► Pressure build-up: Max. 6 bar

► Lubricant volume: 130 cm³

► Housing: Transparent plastics

► Electrochemical / grease and oil / temperature independent

► Operating temperature 10°C to +50°C

► Discharge period: 1, 3, 6, 12 months or machine controlled

► Pressure build-up: Max. 5 bar

► Lubricant volume: 60 cm³, 120 cm³, 250 cm³

► Housing: Metal / transparent plastics

► Electrochemical / grease and oil / temperature independent

► Operating temperature -20°C to +60°C

► Discharge period: 1, 3, 6, 12 months or machine controlled

► Pressure build-up: Max. 25 bar

► Lubricant volume: 250 cm³, 500 cm³

► Number of lubrication points: 2-6